The Copper Recycling Process:

Transforming Scrap into Treasure

In the realm of sustainable resource management, copper stands as a shining example of a metal that can be recycled infinitely without compromising its quality. The copper recycling process not only conserves valuable natural resources but also minimizes environmental impact. Within the confines of a recycling factory, copper undergoes a meticulously orchestrated series of steps, each playing a crucial role in its transformation from discarded scrap to reusable treasure.

Understanding the Significance of the Copper Recycling Process

Copper, a versatile metal with exceptional conductivity and durability, finds extensive use in various industries, including electronics, construction, and transportation. Its ubiquity in modern society underscores the importance of efficient recycling practices. The Copper Recycling Process serves as the linchpin in mitigating the need for continuous mining and refining of copper ore, thus reducing energy consumption and environmental degradation associated with extraction.

Sorting: The Gateway to Copper Recycling

The journey of recycled copper commences with sorting, a fundamental step where scrap materials are categorized based on their copper content and purity levels. Upon arrival at the recycling facility, scrap metal undergoes meticulous segregation, with advanced techniques such as magnetic separation and eddy current sorting employed to distinguish copper-containing materials from other metals. This process ensures that only suitable materials proceed to subsequent stages, streamlining the recycling process and enhancing efficiency.

Shredding: Breaking Down the Barrier

Following sorting, the copper-rich materials are stripped of any other materials such as wire casing and then undergo shredding. Large pieces of scrap are fragmented into smaller, more manageable pieces. High-powered shredders tear through the scrap, reducing it to uniform sizes conducive to downstream processing. Shredding not only facilitates efficient handling but also exposes a greater surface area of copper, optimizing the effectiveness of subsequent processes.

Melting: From Solid to Liquid Gold

The shredded copper scrap is then fed into furnaces for melting, marking a transformative phase in the recycling journey. At elevated temperatures, typically exceeding 1,000 degrees Celsius, the copper undergoes a metamorphosis from solid to molten state. This molten copper, resembling liquid gold, is purified through the removal of impurities such as oxides and contaminants, ensuring the production of high-quality recycled copper ready for reuse in various applications.

Purification: Refining Excellence

Purification stands as a critical stage in the copper recycling process, where molten copper undergoes refining to achieve the desired purity levels. Various methods, including electrolysis and fractional crystallization, are employed to eliminate residual impurities, resulting in copper of exceptional quality meeting industry standards. The short version of fractionalized crystallization is basically forcing the mixed “impure” metals to form crystals. Once the crystals are formed the materials can be cleanly separated.

Electrolysis is a pretty cool process. According to the Arizona University study, linked above, “large slabs of impure copper (called blister copper) are used as anodes and placed in a large vat containing an electrolyte solution of copper sulfate and sulfuric acid. Thin “starter sheets” of highly pure copper foil are used as the cathodes, which are placed in between the anodes. When current is applied (over 200 amperes), copper (as well as other metals) leaves the anode and moves through the solution toward the cathode. The other metals (sometimes valuable, but considered to be impurities in copper processing) either remain in solution or fall to the bottom of the tank, where they can be later captured for use as a by-product. Over the course of 1-2 weeks, the copper ions plate onto the cathode, resulting in a 300-pound sheet of 99.9% pure copper.”

Solidification: Shaping the Future

Upon achieving the desired purity, the molten copper undergoes solidification, where it is cast into molds to form ingots or other shapes suitable for subsequent utilization. Rapid cooling techniques are employed to expedite the solidification process, ensuring the efficient production of copper in its desired form. These solidified copper products serve as the building blocks for diverse applications, ranging from electrical wiring to plumbing fixtures, embodying the cyclical nature of the recycling process.

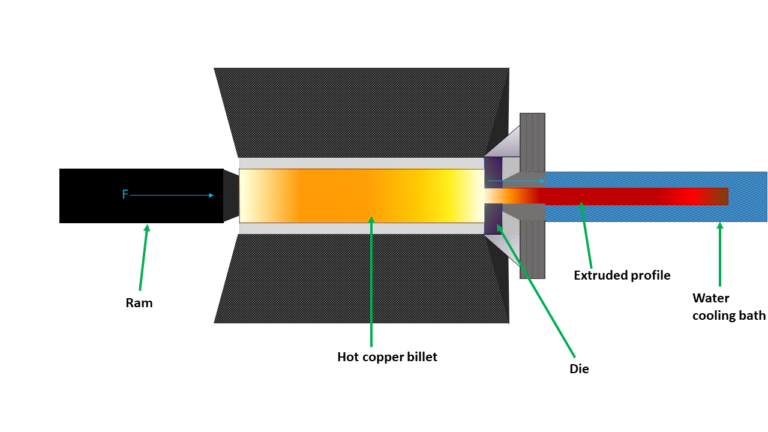

Extrusion and Fabrication: Completing the Copper Recycling Process

In some instances, recycled copper undergoes additional processing through extrusion (forcing the copper into the desired shape, like a tube) and fabrication (forming into sheet metal or bending it) to tailor its properties to specific applications. Extrusion involves forcing the copper through dies to create intricate shapes such as wires, tubes, or profiles, enhancing its versatility and usability. Fabrication techniques, including bending, cutting, and welding, further refine the recycled copper, enabling the creation of custom components tailored to meet the demands of various industries.

The copper recycling process stands as a testament to human ingenuity and environmental stewardship, showcasing the transformative power of recycling in perpetuating the lifecycle of valuable resources. From sorting to fabrication, each step in the process contributes to the efficient reclamation of copper, reducing the reliance on virgin materials while minimizing environmental impact. As industries continue to embrace sustainable practices, the role of copper recycling assumes greater significance, underscoring its pivotal contribution to a greener, more sustainable future.

In summary, understanding how copper is recycled unveils a meticulously orchestrated series of processes within recycling factories, where scrap copper undergoes sorting, shredding, melting, purification, solidification, and fabrication to emerge as a valuable resource ready for reuse. The Copper Recycling Process not only conserves natural resources but also minimizes environmental impact, serving as a beacon of sustainability in an increasingly resource-constrained world.

Next Article: How To Recycle Batteries >